Medical filters for insufflators are a small but critical component in laparoscopic and robotic surgery. Insufflators generate and regulate the carbon dioxide (CO₂) pneumoperitoneum that creates working space inside a patient’s abdomen. A dedicated in-line filter prevents particulate matter, microbes, oil, and condensate from traveling from the insufflator to the patient, protecting wound sites and reducing postoperative infection risk. This article explains how these filters work, key specifications clinicians and procurement teams should consider, and best-practice guidance for selection and use.

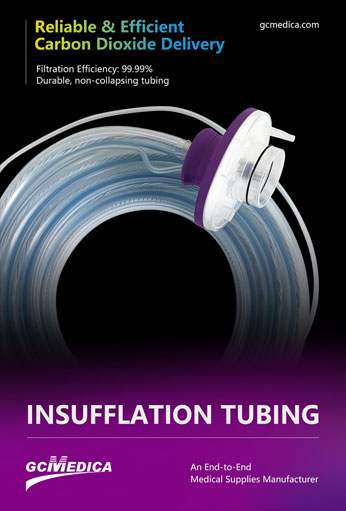

Insufflator filters typically combine mechanical depth filtration with hydrophobic membranes to trap particles and block fluid ingress while preserving high gas flow. Important performance metrics include filtration efficiency (often expressed as % removal at a target particle size such as 0.2–0.3 µm), maximum continuous flow rate (L/min), pressure drop at operating flow, compatibility with standard trocar fittings and tubing, and sterilization or packaging state (sterile single-use vs. reusable). For many operating rooms, single-use sterile filters are preferred to avoid cross-contamination and simplify logistics.

Clinically, an effective filter reduces the chance of aerosolized contaminants or condensed fluids entering the insufflation circuit. In addition to infection control, filters help maintain insufflator performance by keeping internal valves and sensors free of particulate and oil. For surgeries that generate surgical smoke (e.g., electrocautery or laser), the filter’s ability to capture fine particulates is especially valuable; however, smoke evacuation systems remain a separate requirement for smoke management.

When selecting a medical filter for an insufflator, balance these criteria:

Filtration efficiency at targeted particle sizes (higher is better for microbial and smoke particulates);

Low pressure drop to avoid compromising insufflation pressure or flow;

Connector compatibility (Luer, ISO adapters, or manufacturer-specific fittings);

Sterility and shelf-life;

Regulatory approvals and testing documentation (e.g., ISO 13485, EN/ASTM standards);

Cost per use and environmental considerations (single-use waste vs. validated reprocessing).

Below is a compact comparison table for quick reference.

| Parameter | Typical Target / Recommendation |

|---|---|

| Filtration efficiency | ≥99.999% @ 0.2–0.3 µm (for microbial protection) |

| Max continuous flow | 15–30 L/min (match insufflator capability) |

| Pressure drop | <5 cmH₂O at nominal flow (minimizes flow impedance) |

| Membrane type | Hydrophobic PTFE / depth filter composite |

| Sterility | Gamma-sterilized, single-use preferred |

| Connectors | Universal Luer / ISO 5356 / manufacturer-specific adapters |

| Shelf life | 3–5 years typical (check batch certificate) |

| Waste | Single-use medical waste; consider biodegradable packaging options |

Best practice: install the filter close to the insufflator outlet, inspect packaging integrity before use, and replace the filter for each procedure. If a reusable filter is considered, ensure validated sterilization cycles and traceable reprocessing records.

Medical filters for insufflators are essential for maintaining aseptic gas delivery during minimally invasive surgery. Choosing the right filter involves assessing filtration efficiency, flow capacity, pressure drop, connector compatibility, and regulatory evidence. For most facilities, a sterile single-use hydrophobic filter that achieves very high microbial removal with minimal pressure loss offers the best mix of safety and convenience. Proper installation and single-procedure replacement complete a practical infection-control strategy that protects patients and preserves insufflator performance.

| Insufflation Tubing and Filters for Insufflators > |

Français

Français Español

Español Products

Products

About Us

About Us