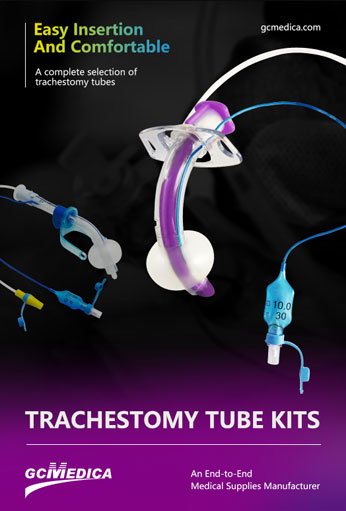

Tracheostomy tubes are critical devices used to maintain airway patency in patients who require long-term ventilation or airway protection. Two common materials for these tubes are stainless steel (metal) and medical‐grade plastics (such as silicone or PVC). Each material offers distinct advantages and disadvantages in terms of mechanical performance, biocompatibility, patient comfort, radiographic visibility, infection risk, and cost. Clinicians must weigh these factors when selecting the most appropriate tube for individual patients, considering factors such as the expected duration of use, frequency of tube changes, patient anatomy, and sensitivity to materials.

Below is a comparative table summarizing the most important characteristics of metal versus plastic tracheostomy tubes:

| Feature | Metal Tracheostomy Tube | Plastic Tracheostomy Tube |

|---|---|---|

| Material Properties | Rigid stainless steel alloy; high structural integrity | Flexible silicone or PVC; softer, conforms to tracheal anatomy |

| Biocompatibility | Inert but may cause mucosal irritation over time | Generally well tolerated; smoother surface reduces mucosal trauma |

| Flexibility | Minimal flexibility; fixed shape | High flexibility; adapts to neck movements and coughing |

| Radiopacity | Intrinsically radiopaque—easily seen on X-ray | Often requires radiopaque markers embedded in the wall |

| Durability | Excellent long-term durability; resists cracking and wear | Moderate durability; may become brittle after repeated sterilization or over time |

| Infection Risk | Smooth metal surface resists biofilm formation but difficult to clean | Silicone is easy to clean; PVC may harbor biofilms if not changed regularly |

| Customizability | Custom-made sizes for complex anatomy | Standardized sizes; available in a wide range of diameters and lengths |

| Cost | Higher initial cost; long useful life offsets expense | Lower initial cost; may require more frequent replacement |

In more detail, metal tracheostomy tubes are favored when long-term use is anticipated. Their rigid structure ensures consistent lumen patency and minimizes risk of kinking. Because stainless steel is intrinsically radiopaque, tube position can be easily confirmed on chest radiographs without additional markers. However, the rigidity may cause patient discomfort, especially during movement or coughing, and may irritate the tracheal mucosa over prolonged periods. Custom metal tubes can be manufactured to accommodate unusual anatomies but incur a higher upfront cost.

Plastic tubes—typically constructed from medical-grade silicone or polyvinyl chloride (PVC)—are more flexible and conform to the patient’s neck movements, improving overall comfort. Silicone variants, in particular, have a smooth surface that resists biofilm formation and is generally easy to clean, which may reduce the risk of infection. PVC tubes are less expensive but can become brittle after repeated sterilization cycles or extended use. Because plastics are less radiopaque, manufacturers embed thin metal or barium sulfate markers in the tube wall to ensure visibility under fluoroscopy or X-ray.

When choosing between metal and plastic, clinicians should consider patient-specific factors: patients with severe neck mobility issues or anatomical irregularities may benefit from a custom metal tube, while those requiring frequent tube changes or desiring greater comfort may prefer plastic. Additionally, facility resources and cost constraints play a role: initial investment in metal tubes can be offset by their longevity, whereas plastic tubes’ lower unit cost may be preferable in high-turnover settings.

In summary, both metal and plastic tracheostomy tubes serve essential roles in airway management. Understanding their comparative properties—mechanical, biological, and economic—enables healthcare providers to tailor device selection to each patient's clinical scenario, ultimately optimizing safety, comfort, and cost-effectiveness.

| Tracheostomy Tubes > |

Français

Français Español

Español Products

Products

About Us

About Us